Overhead Conveyor

Reliable Overhead Movement for Every Industry

What is an Overhead Conveyor?

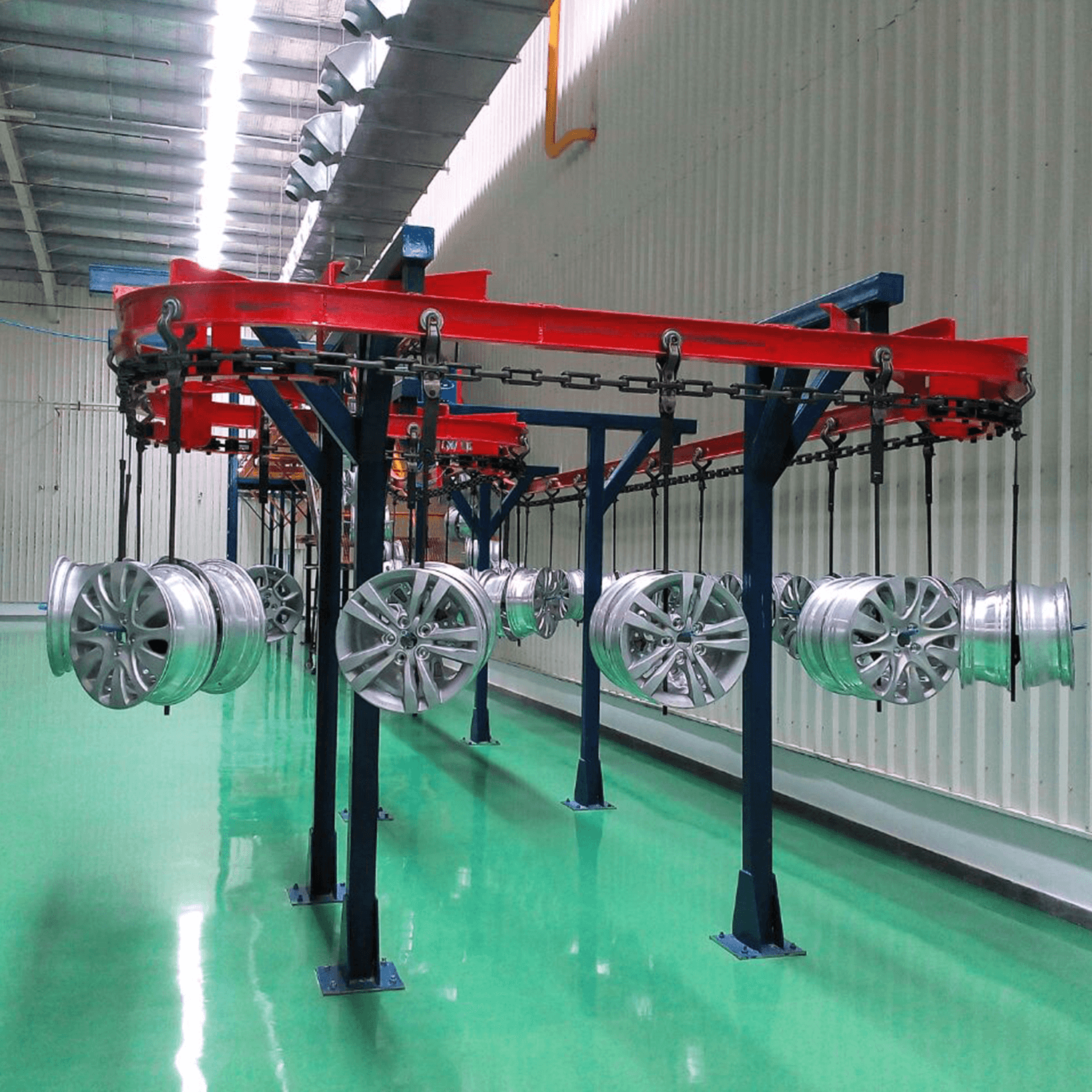

An Overhead Conveyor System is a highly efficient material handling solution used to transport loads, components, or products along a fixed path above the ground level. Unlike traditional floor conveyors, overhead systems use an elevated track structure — typically suspended from the ceiling or supported by a frame — to carry materials through various stages of production, assembly, painting, packaging, or storage.

By moving products above the workspace, these conveyors free up valuable floor area, enabling a cleaner, safer, and more organized working environment. This makes them a key component in lean manufacturing and smart factory setups.

How Overhead Conveyors Work?

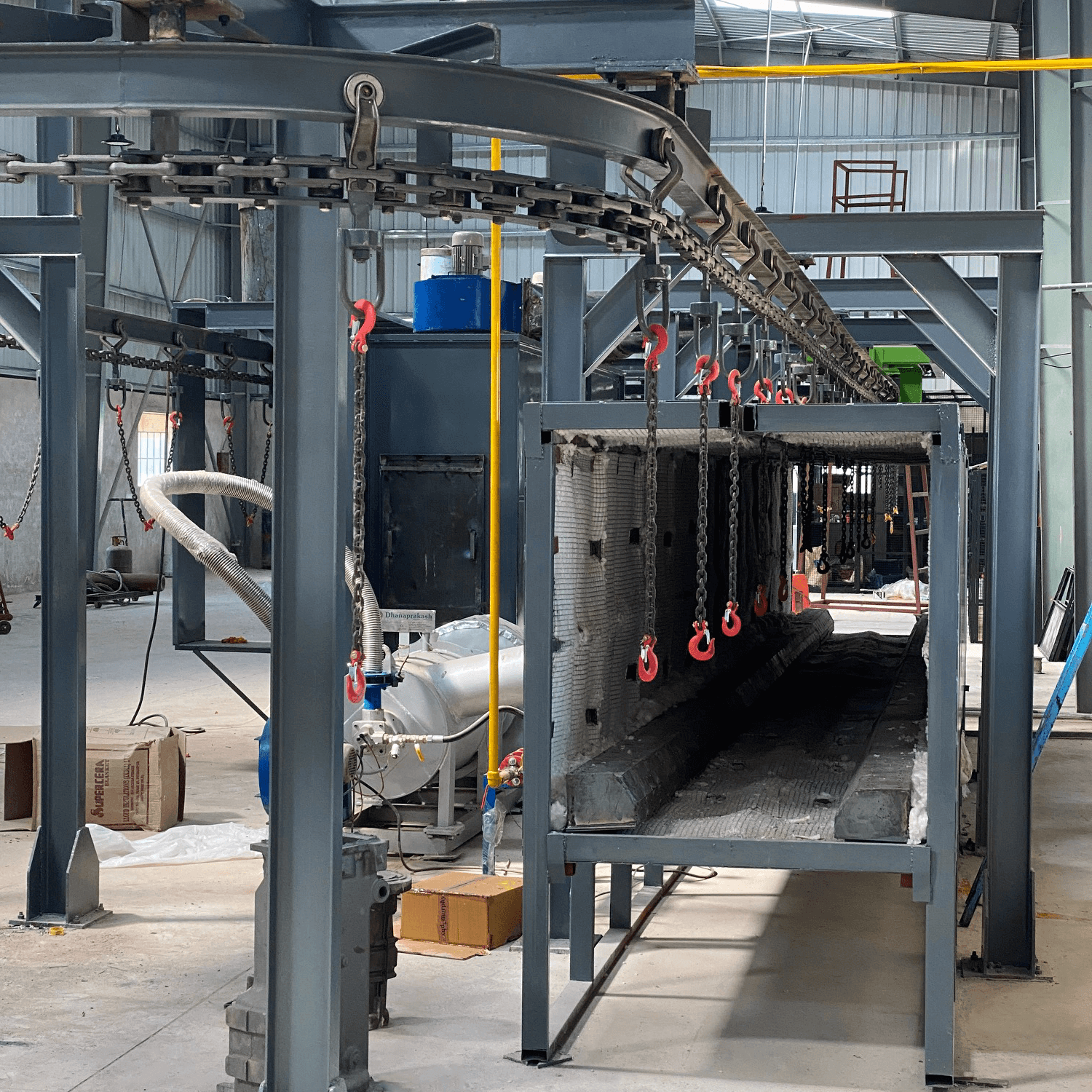

Overhead conveyors operate using a continuous chain that drives a series of trolleys, hooks, or carriers along a track or rail system. The products are suspended from the trolleys and can move in straight, curved, or looped paths, making them suitable for complex plant layouts. These systems can be manual, motor-driven, or fully automated, depending on the operational need.

Types of Overhead Conveyors

I-Beam Overhead Conveyor

An I-Beam Overhead Conveyor uses heavy-duty forged chain and trolley design running on an open I-beam structure — suitable for high-capacity and rugged applications like automotive assembly.

Key Features and Benefits

Open I-Beam Track

Simple and rugged structure for easy inspection and maintenance.

Continuous or Indexed Drive

Supports heavy or batch-type movement.

Heavy-Duty Construction

Designed for high-strength and durability.

Power & Free Overhead Conveyor

A Power & Free Overhead Conveyor is an advanced dual-track system that offers maximum flexibility and control. The “power” track drives the chain, while the “free” track allows individual carriers to accumulate, stop, or divert independently — ideal for automated and high-mix production systems.

Key Features and Benefits

Dual Track Design

Separate “power” and “free” rails for flexible carrier control.

Independent Movement

Carriers can start, stop, accumulate, or bypass others.

Load Capacity

Designed to handle various items, making it suitable for industrial environments.

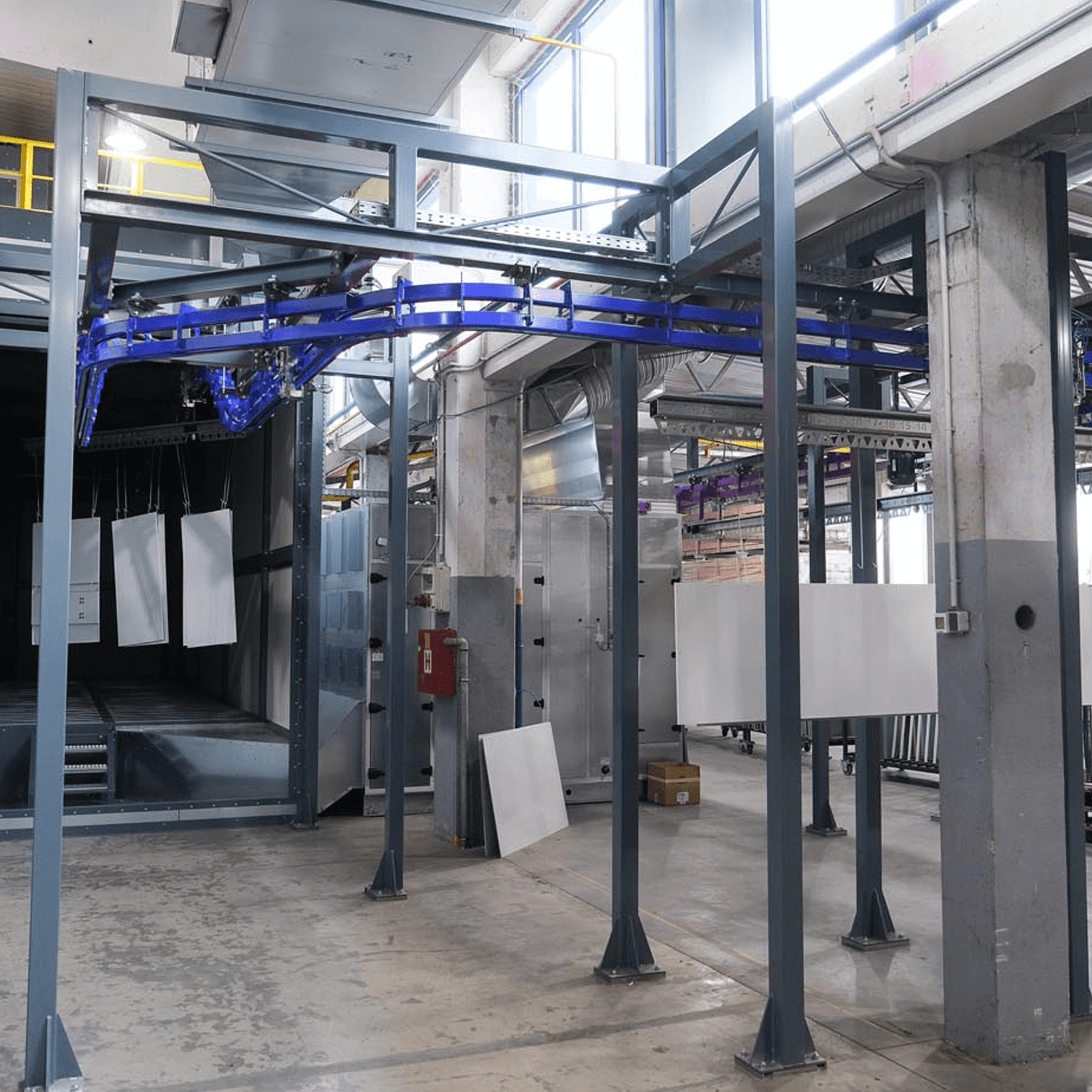

Enclosed Track Overhead Conveyor

An Enclosed Track Overhead Conveyor uses a closed tubular or rectangular rail where the moving chain and trolleys are fully protected inside the track. This design minimizes contamination from dust, dirt, and debris — making it ideal for cleanroom environments, paint shops, and light assembly lines.

Key Features and Benefits

Enclosed Rail Structure

Protects chain and trolley from dust, moisture, and contaminants.

Compact Design

Suitable for light to medium-duty applications.

Quiet Operation

Low-friction design ensures smooth and silent running.

Applications Across Industries

Manufacturing

An Overhead Conveyor is a highly efficient solution for transporting, assembling, and staging products across production lines. By suspending the conveyor system above the floor, it frees up valuable workspace while ensuring smooth and continuous material flow.

Food and Beverage

An Overhead Conveyor provides a hygienic, efficient, and space-saving solution for transporting products across production and packaging areas. By elevating the conveyor above the floor, it maximizes workspace utilization and ensures a smooth, continuous flow of goods such as bottles, cans, cartons, and packaged food products.

Pharmaceuticals

In the pharmaceutical and healthcare industry, an Overhead Conveyor provides a safe, hygienic, and efficient material handling solution for transporting sensitive products such as medicine boxes, medical kits, lab samples, and packaged healthcare items.