Roller Conveyor System

Roller Conveyor System: Material Handling Solution for Every Industry

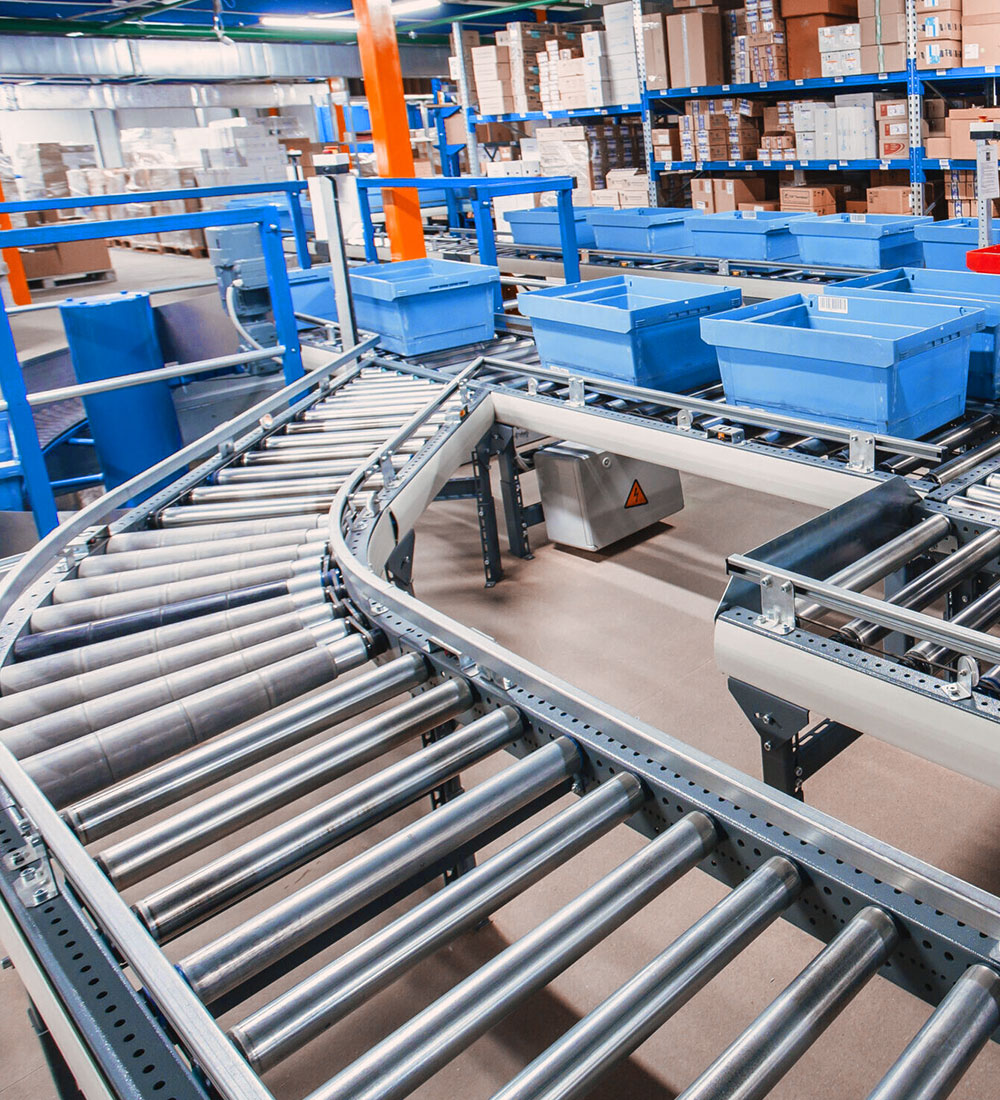

Types of Roller Conveyor Systems

Gravity or Non-powered Roller Conveyor

The gravity roller conveyor relies on gravity to move items along the system, making it a low-cost solution for transporting lighter loads over shorter distances.

Powered Roller Conveyor

Flexible Roller Conveyor

A flexible roller conveyor provides adaptability and flexibility in layout design. These systems can be extended, contracted, or reconfigured to suit changing operational needs.

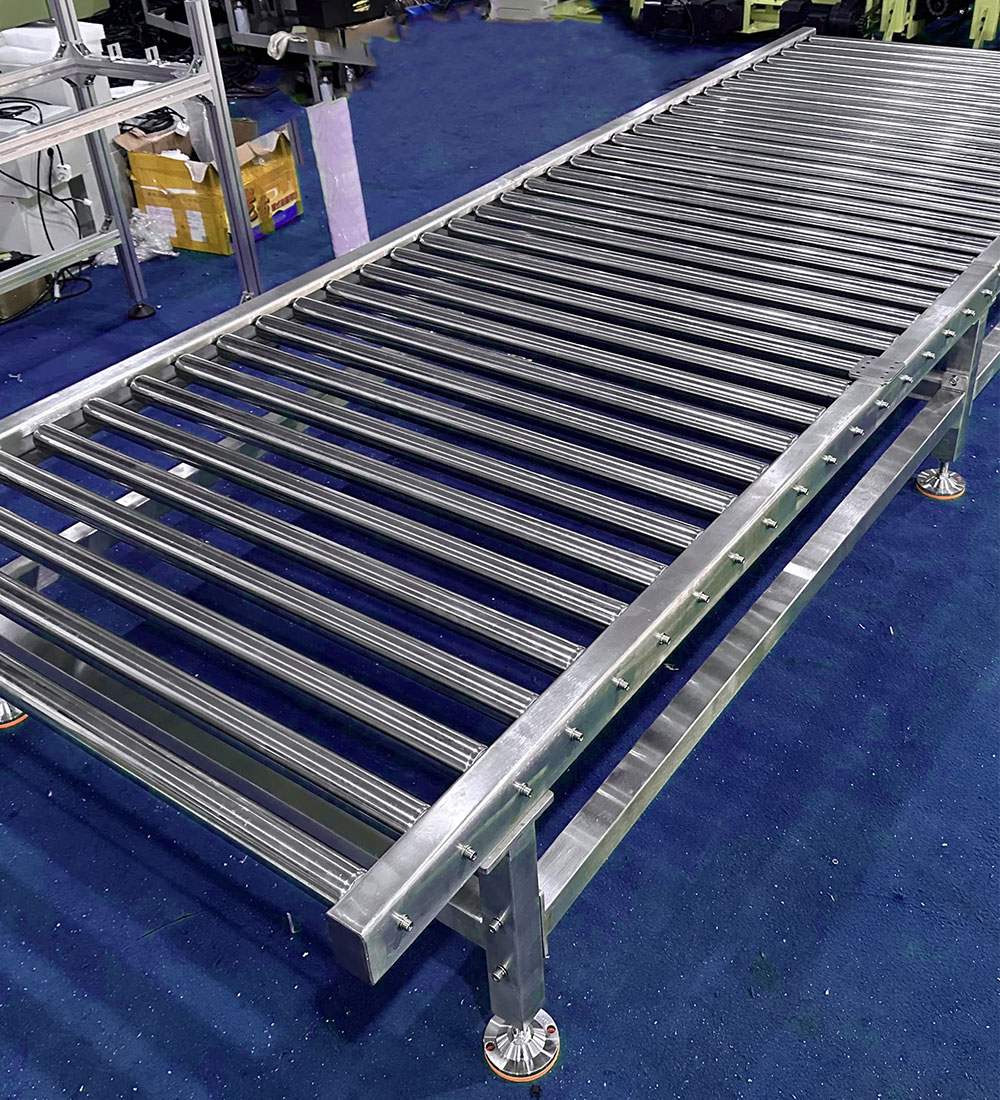

Pallet Roller Conveyor

The pallet roller conveyor is specifically designed to move palletized goods efficiently. With its durable rollers, this conveyor can handle heavy items like wooden, plastic, and steel pallets.

Chain Driven Roller Conveyor

Key Features and Benefits

Increased Productivity

Roller conveyors automate the movement of materials, ensuring continuous workflow and reducing handling time, which ultimately boosts overall productivity.

Reduced Risk of Injury

With the automation of material handling, roller conveyors reduce the need for heavy lifting, minimizing the risk of workplace injuries.

Customizable Solutions

With various types of roller conveyors available, businesses can select the system that best meets their specific material handling needs.

Scalability

As your business grows, roller conveyor systems can easily be scaled to accommodate increased volume, ensuring long-term efficiency.

Applications Across Industries

Manufacturing and Assembly

Roller conveyors are crucial for moving parts and components along assembly lines, increasing efficiency in automated production systems.

Food and Beverage Industry

Used for transporting food products in various stages of processing, roller conveyors help streamline operations in food packaging, sorting, and quality control.

Logistics and Warehousing

In distribution centers and warehouses, roller conveyors improve the movement of packages, boxes, and palletized goods, enabling faster order processing and shipping.

Automotive Industry

Roller conveyors play an essential role in the automated assembly lines of the automotive industry, moving automotive parts, engines, and components for assembly and testing.

Frequently Asked Questions

1. What types of roller conveyors does ATMOS Systems offer?

ATMOS Systems offers roller conveyors including gravity roller conveyors, powered roller conveyor systems, expandable roller conveyors, flexible roller conveyors, and pallet roller conveyors.

2. What is the difference between gravity roller conveyors and powered roller conveyors by ATMOS Systems?

Gravity roller conveyors by ATMOS Systems rely on slope or manual push, while powered roller conveyors use motors to move loads automatically at controlled speeds.

3. What is a Flexible Roller Conveyor by ATMOS Systems?

A Flexible Roller Conveyor by ATMOS Systems is a mobile and adjustable conveyor that can curve and extend, making it ideal for flexible warehouse operations.

4. Can ATMOS Systems design gravity conveyor systems for heavy loads?

Yes, ATMOS Systems designs gravity conveyor systems with heavy-duty rollers and reinforced frames suitable for palletized and bulk loads.

5. What materials are used in ATMOS Systems roller conveyors?

ATMOS Systems roller conveyors use high-quality steel, galvanized rollers, stainless steel (for hygienic areas), and durable bearings for long service life.